Mar 29,2024

Mar 29,2024

BSL

BSL

Zipper

A connecting piece consisting of two flexible tooth chain belts that can mesh with each other and a pull head that can be pulled apart and closed repeatedly.

Teeth

Teeth made of metal, plastic, and other materials are processed into a certain shape.

Teeth chain

Continuously arranged zipper elements. The moving parts engage and pull apart the tooth chains on both sides.

Top stop

A stopper is fixed on the tooth chain belt to restrict the slider from sliding out of the tooth chain belt when the tooth chain is closed.

Bottom stop

A stopper that is fixed on the chain belt prevents the slider from sliding out of the chain belt when the chain is pulled open and prevents the two sides of the chain belt from being completely separated.

Tape

A flexible belt woven from cotton yarn, chemical fiber, or mixed chemical fiber, is used to carry fastener elements and other zipper components.

Auto lock slider

The nose of the slider has a small self-locking stopper. Under the action of spring force, it can automatically embed between the chain elements to lock the slider. When opening and closing the zipper, lift the pull tab to drive the small stopper away from the chain elements, thereby moving the slider.

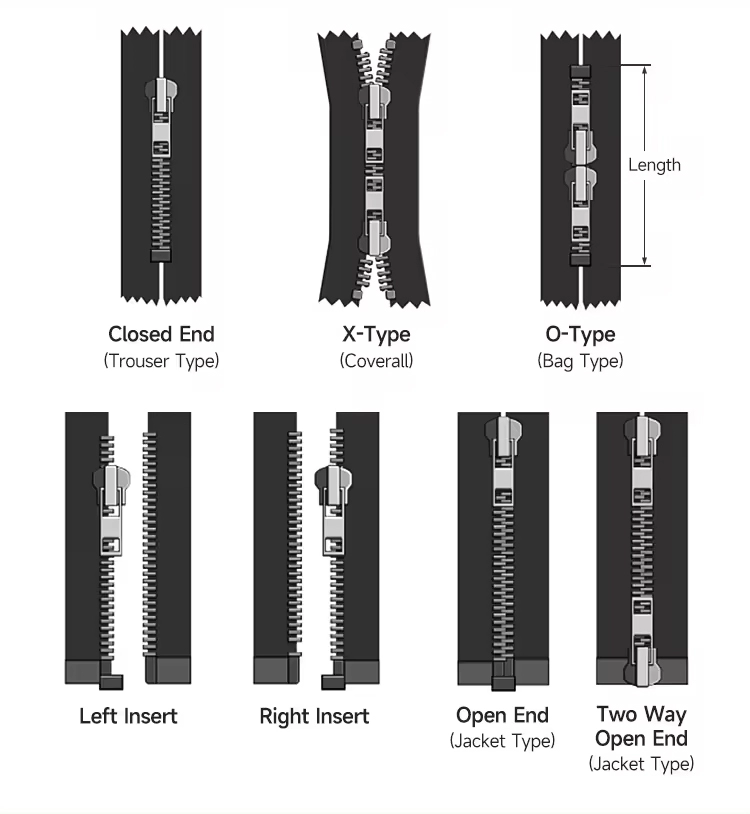

Closed-end

When the zipper is opened, the tooth chain straps on both sides cannot be completely separated.

Open-end zipper

When the zipper is opened, the tooth chain straps on both sides can be completely separated.

Two-way open-end zipper

Wear an open-tail zipper with two sliders, pull the two sliders to the end, and the intubation tube can be pulled out from the two slider bodies so that the two tooth chain belts are detached; when the two sliders are on the tooth chain belt At the tail end, insert the cannula on the other side into the two puller bodies to pull them together.

In spear/chain zipper

Zippers are packaged, stored, and sold in units of strips/length.

Cloth tape: The cloth tape should be dyed evenly, without dirt or indentation, and should be soft to the touch. The edge of the cloth tape should be slightly wavy.

Chain elements: The surface of the chain elements should be smooth and feel soft and smooth when pulled open.

Slider: The self-locking slider is easy to pull up and locks firmly without slipping.

Patch: The patch is tightly buckled with the tape and is not easy to break or fall off.

Squares and latches: can be inserted freely and fastened with cloth straps.

Upper stop and lower stop: The lower stop is fastened to the teeth or embedded on them, firmly and flatly. The upper stop should be tightly connected to the first tooth (metal, nylon), the distance should not exceed 1mm, and it should be strong and beautiful.

Since zippers have different adaptability in different environments, when purchasing zippers, you should specifically mention the following to the manufacturer:

one. What type of products should the zipper be used on (such as bags, shoes, ski jackets, raincoats, tents, denim, and leather products) or other special requirements?

two. Regarding the requirements for the zipper composition, are there any environmental requirements such as being free of ammonia (AZO) and nickel, or can it pass a needle detector, etc?

During the zipper production process, affected by the mechanical speed, process conditions, and chain belt tension, natural tolerances will occur on the chain, and the longer the zipper length, the greater the tolerance will be.