Plastic zippers usually have a higher grade and fashion sense

The rich, solid hand of genuine plastic elements imparts a sense of value and permanence to your products. Made of durable, tarnish-resistant brass alloys, plastic zippers are offered in a multitude of metal finishes to complement the designer's pallet. A wide range of tape and slider options completes the picture

1. Lightweight: Plastic zippers are usually lighter than metal zippers, which is very beneficial for some applications that require weight reduction, such as lightweight outdoor products, sports equipment, etc.

2. Rust-proof and corrosion-resistant: Plastic zippers are not prone to rust, while metal zippers are susceptible to oxidation, corrosion and other problems. This makes plastic zippers more suitable for use in wet and humid environments.

3. Low temperature resistance: Plastic zippers usually remain flexible in low temperature environments, while metal zippers may become more fragile and easily damaged in cold conditions.

4. Color selection: Plastic zippers can achieve rich color selections through dyeing and other methods, making it easier to match product design and personalized needs.

5. Silent operation: Compared with metal zippers, plastic zippers are usually quieter during use and will not produce harsh friction sounds.

6. Lower cost: The cost of manufacturing plastic zippers is usually relatively low, which contributes to their widespread use in some affordable products.

7. Environmental protection: Some plastic zippers are recyclable, and relatively little waste is generated during the production process, which helps reduce the environmental burden.

Plastic zipper opening type

1. Pin and Box: This is a common type of opening in which one sliding part has a pin and the other sliding part has a box into which the pin can be inserted to close it.

2. Straight-cut: This is a simple opening design where the zipper ends are cut directly with no additional decoration or structure.

3. U-shaped opening: This design forms a U-shaped opening at both ends of the zipper, which is suitable for applications that require quick connection or separation at both ends.

4. L-shaped opening: An "L"-shaped opening is formed at both ends of the zipper. This design is common in products that need to be fixed or locked.

5. Seamless opening (Continuous): The two ends of the zipper are seamlessly connected to form a continuous loop, suitable for recycling or products that need to move freely.

6. Self-locking opening (Auto-lock): This opening design allows the zipper to automatically lock after closing without additional operations.

7. Two-way opening: This design allows the zipper to be opened from two directions, increasing the flexibility and convenience of the product.

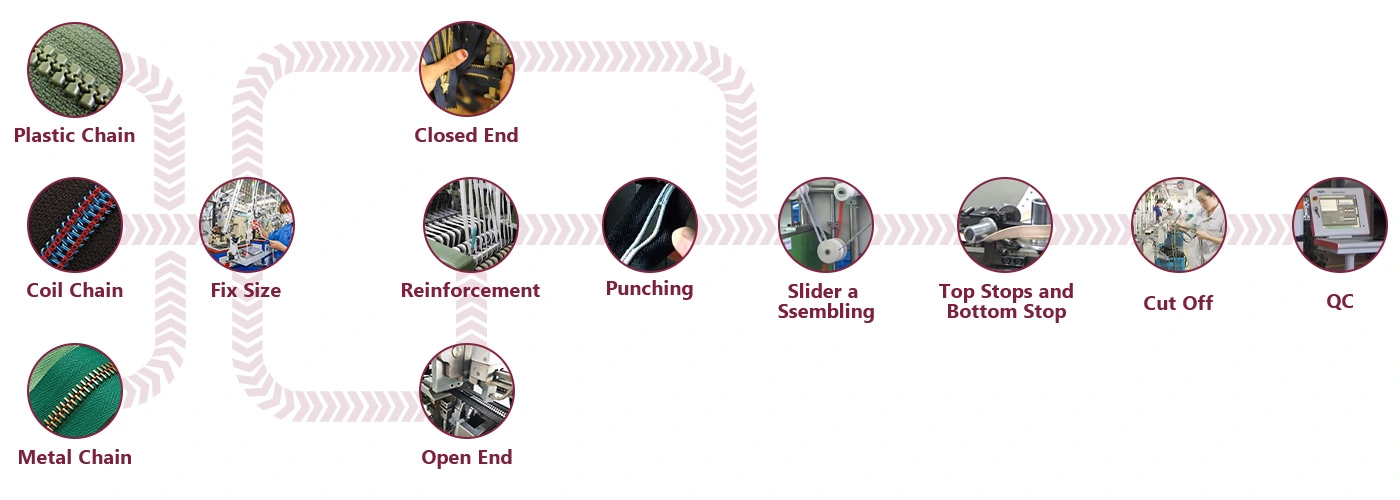

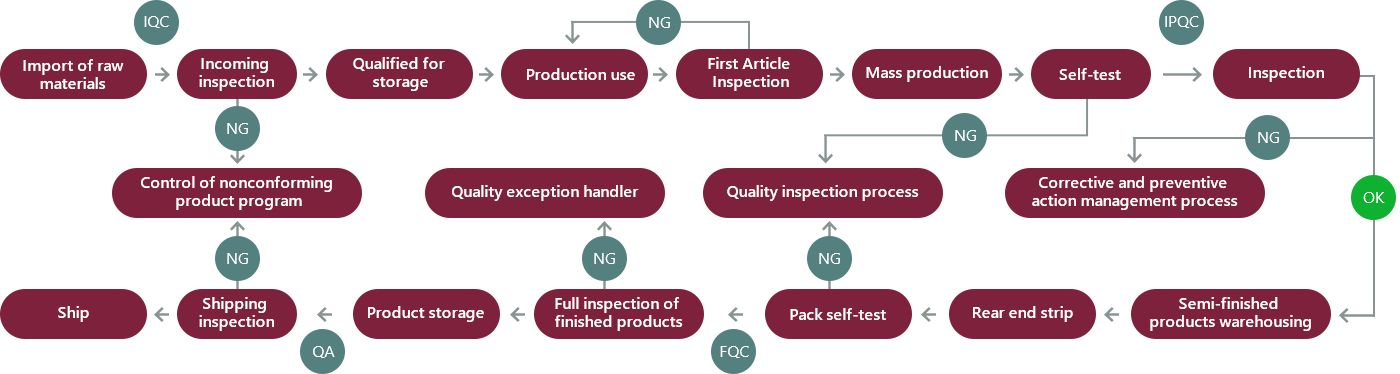

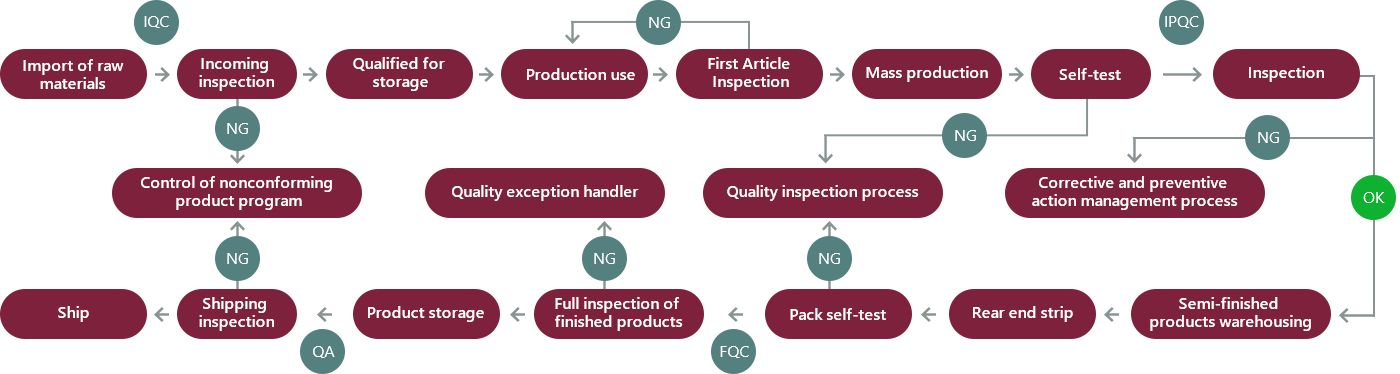

Process

One-stop production of webbing, dyeing, mold making, design, etc., plastic, coil, metal zippers of various specifications.

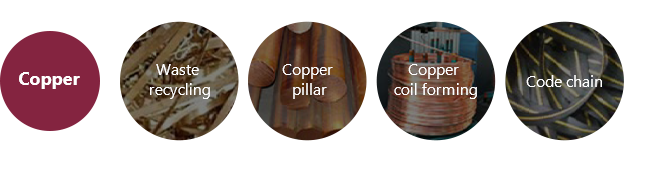

Baoxin has a high degree of environmental awareness. We have a complete environmentally friendly material recycling system to reduce factory waste residues. Not only have the chain elements been fully recycled and non-toxic regenerated cloth belts have also been manufactured using environmentally friendly materials. Currently, some of Baoxin's products have been made from 100% environmentally friendly materials, fully reducing the loss of earth resources and environmental pollution.

Shenzhen Baoxin Zipper Co., Ltd was founded in 1991, the total investment has exceeded RMB 100 million. The factory covers an area of 30,000 square meters and has more than 300 employees, with annual capacity exceeding 200 million meters. It has developed into a large zipper enterprise integrating research, development, design, production, sales and services. The company is currently a director unit of the Zipper Branch of China Hardware Products Association, and the executive vice president unit of the Guangdong Zipper Chamber of Commerce, the executive director unit of the Shenzhen Small and Medium Enterprises Development Promotion Association, the vice president of the Shenzhen Quality Association, and an outstanding enterprise in the zipper industry.

30 years experience in zipper industry. The factory covers an area of 30,000 square meters. Has more than 300 employees. With annual capacity exceeding 200 million meters.

The products have passed ISO9001 quality managementsystem certification, OKO-TEXSTANDARD100, environmental certification, HIGGSEDEXGRS. we have integrated development, production, salesand design.

we offer samples for free, you just undertake the charge of delivery, better to provide your DHL account if you have one. If you don't know the specifications of the sample, please kindly tell us what it will to be made, and then we will suggest the available product to you.

Productive Capacity: With advanced equipment and our efficient teamwork, annual capacity that more than 30,000 square meters can be created for all clients.

Materials (Nylon zipper; Plastic zipper; Metal zipper; Waterproof zipper,Ect.) Style (Open End, Closed End, Double Closed End X Type, Double Closed End O Type, Double Open End,Ect.)

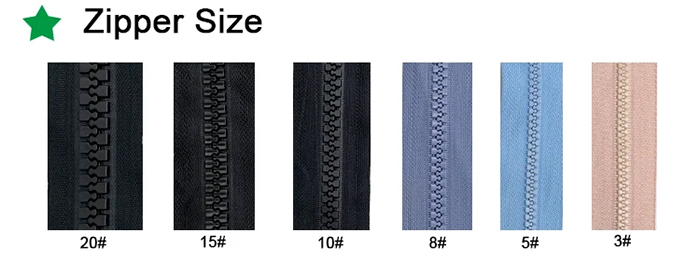

Size (#3, #4, #5, #7, #8, #10) Color (Customized Color Based On Your Fabric Colors) Customized Zipper Puller (Customized Shape, Size, Logo, Color, Material)