Excellent enterprise in the zipper industry

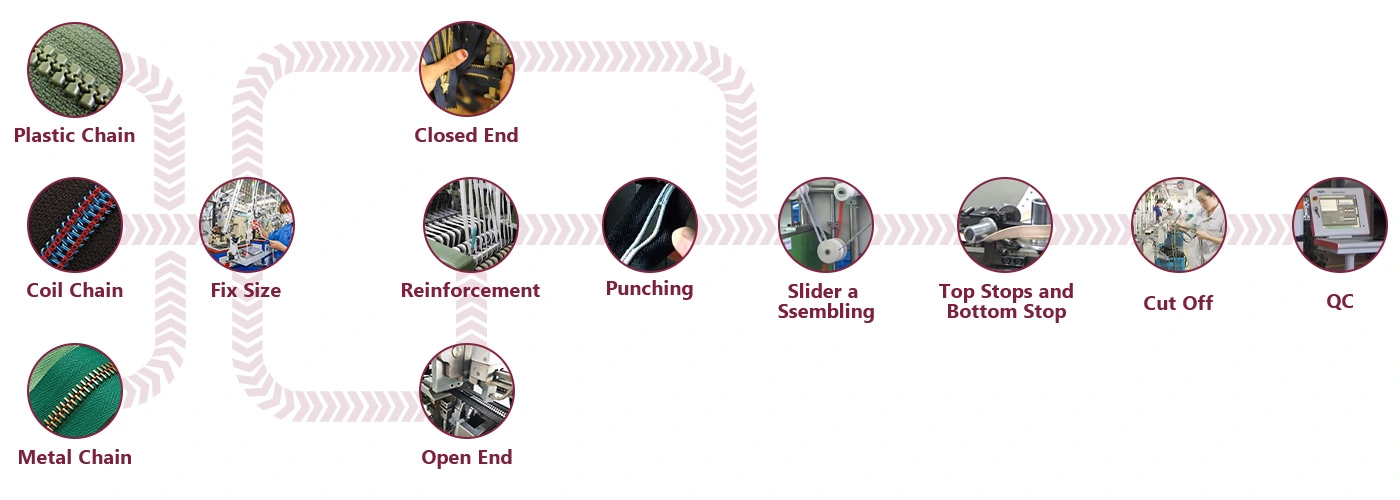

One-stop production of webbing, dyeing, mold making, design, etc., coil, plastic, and metal zippers of various specifications.Clarify requirements: Determine the zipper’s purpose, size, color, material, and other requirements.

Communicate design: Discuss the design details of the zipper, such as the shape of the slider, the shape of the zipper teeth, etc.

Material selection: Make sure the selected materials meet recyclable environmental standards.

Sample confirmation: Require suppliers to provide samples for testing and confirmation.

Mass production: Determine the production quantity according to demand and carry out production.

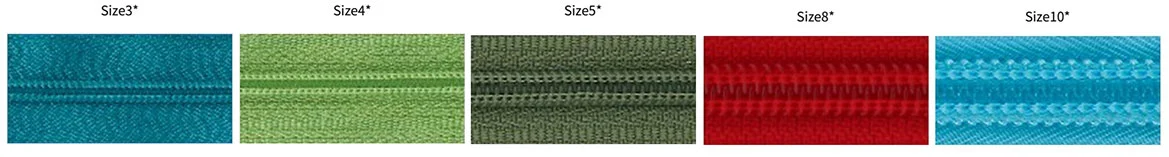

| Size / Chain Type | Classification | |||

|---|---|---|---|---|

| Close | Open | Two-way | Chain | |

| No. 3 invisible mesh | OK | / | / | OK |

| No. 4 invisible mesh | OK | / | / | OK |

| No. 3 | OK | OK | / | OK |

| No. 4 | OK | OK | / | OK |

| No. 5 | OK | OK | OK | OK |

| No. 8 | OK | OK | OK | OK |

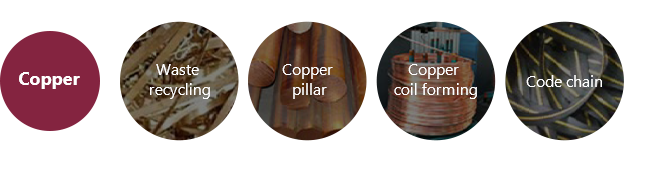

Material recyclability: Choose recyclable materials, such as renewable fibers or recyclable plastics.

Durability: Make sure the zipper has enough strength and durability to meet the needs of use.

Environmental protection standards: Comply with relevant environmental protection regulations and standards.

Zipper type: such as invisible zipper, metal zipper plastic zipper, etc., selected according to product requirements.

Compatibility: Compatible with other materials and components of the product.

Sustainability: Consider sustainability across the entire supply chain.

Innovation: Explore new materials and designs to improve recyclability and environmental performance.

Customer needs: Meet customer requirements for environmental protection and recyclability.

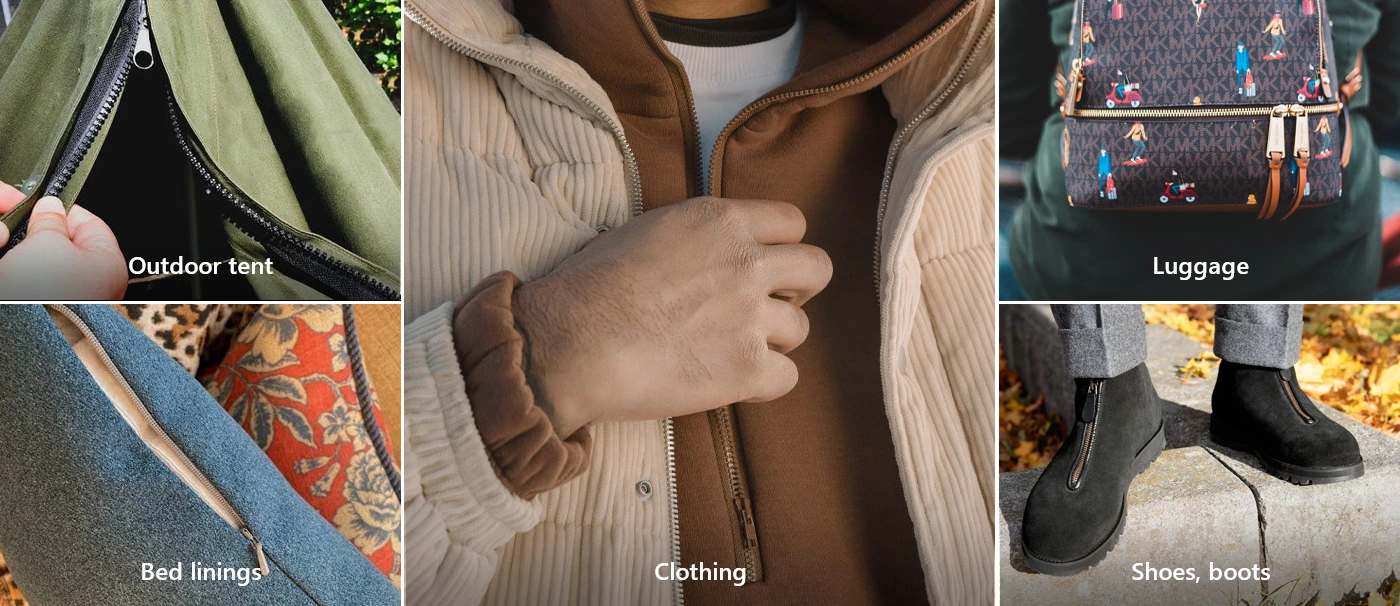

Used in all types of clothing, bags, outdoor equipment, household items, car seats, environmentally friendly toys, and other sustainable products with zippers. Through application in these fields, recyclable environmentally friendly zippers help reduce the impact on the environment and promote sustainable development.

Baoxin has a high degree of environmental awareness. We have a complete environmentally friendly material recycling system to reduce factory waste residues. Not only have the chain elements been fully recycled and non-toxic regenerated cloth belts have also been manufactured using environmentally friendly materials. Currently, some of Baoxin's products have been made from 100% environmentally friendly materials, fully reducing the loss of earth resources and environmental pollution.

Shenzhen Baoxin Zipper Co., Ltd was founded in 1991, the total investment has exceeded RMB 100 million. The factory covers an area of 30,000 square meters and has more than 300 employees, with annual capacity exceeding 200 million meters. It has developed into a large zipper enterprise integrating research, development, design, production, sales and services. The company is currently a director unit of the Zipper Branch of China Hardware Products Association, and the executive vice president unit of the Guangdong Zipper Chamber of Commerce, the executive director unit of the Shenzhen Small and Medium Enterprises Development Promotion Association, the vice president of the Shenzhen Quality Association, and an outstanding enterprise in the zipper industry.

We are a zipper manufacturer in Shenzhen, China. A large zipper enterprise integrating research, development, design, production, sales, and service, specializing in zipper R&D and sales for 32 years.

Generally, it is 5-15 working days. It also depends on the order quantity and product type. If in stock, it can be shipped within one day.

Yes, we provide samples for free.

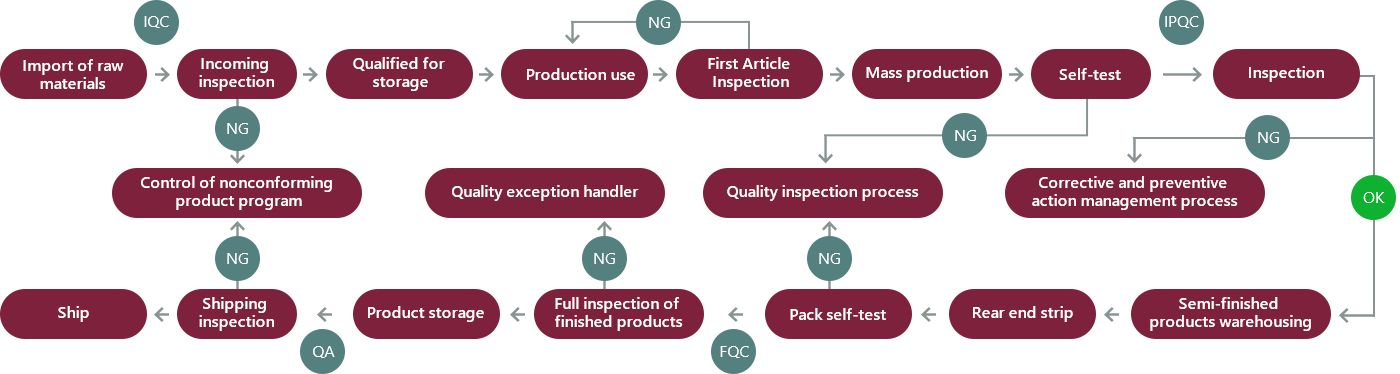

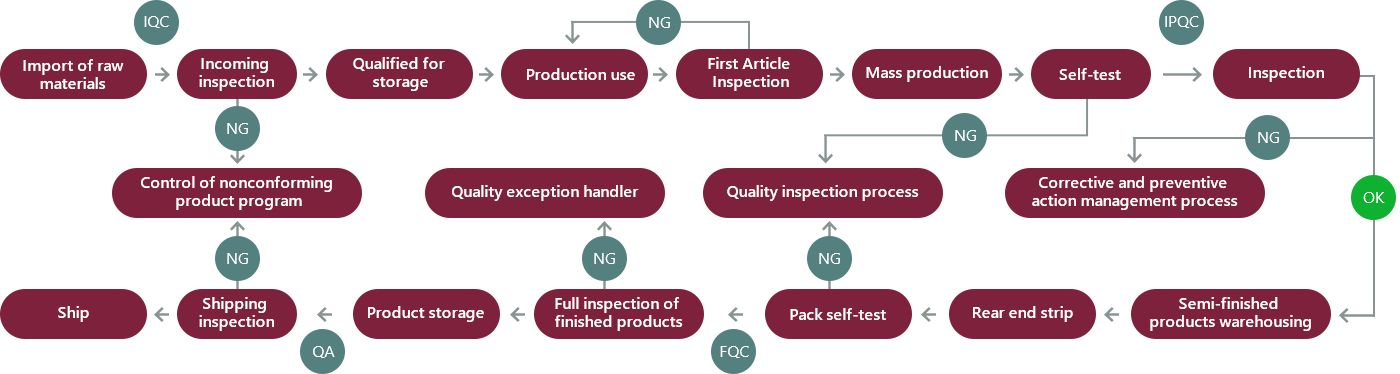

Always have pre-production samples before mass production; always have a final inspection before shipment;

If we have stock, we can accept small orders, but the MOQ of different styles fluctuates.

Of course, all products are environmentally friendly.