Excellent enterprise in the zipper industry

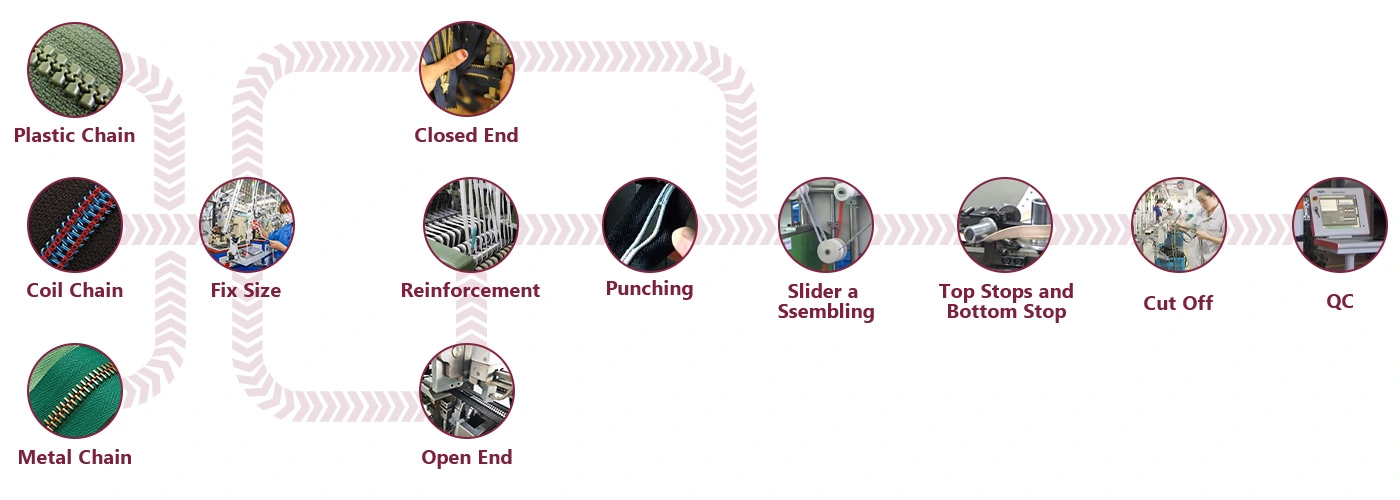

One-stop production of webbing, dyeing, mold making, design, etc., coil, plastic, and metal zippers of various specifications.

Fully communicate with customers to understand their needs and requirements, including zipper length, color, material, specifications, etc.

Determine the usage scenario and environment of the product to select appropriate recycled materials and design options.

Choose recycled materials that meet environmental protection standards, such as recycled nylon, recycled polyester, etc., as the raw materials for coil zippers.

Select appropriate recycled materials according to customer requirements and product design to ensure that products meet environmental protection requirements.

Design the structure and details of the coil zipper, including the shape, size, density, etc. of the coil.

Make preliminary samples and manufacture recycled coil zippers that meet the requirements according to the design plan.

Samples are tested and evaluated to ensure their quality and performance meet expectations and meet customer needs.

Submit samples to customers for confirmation and evaluation, and listen to customers' opinions and suggestions.

Make adjustments and modifications based on customer feedback until the customer is satisfied.

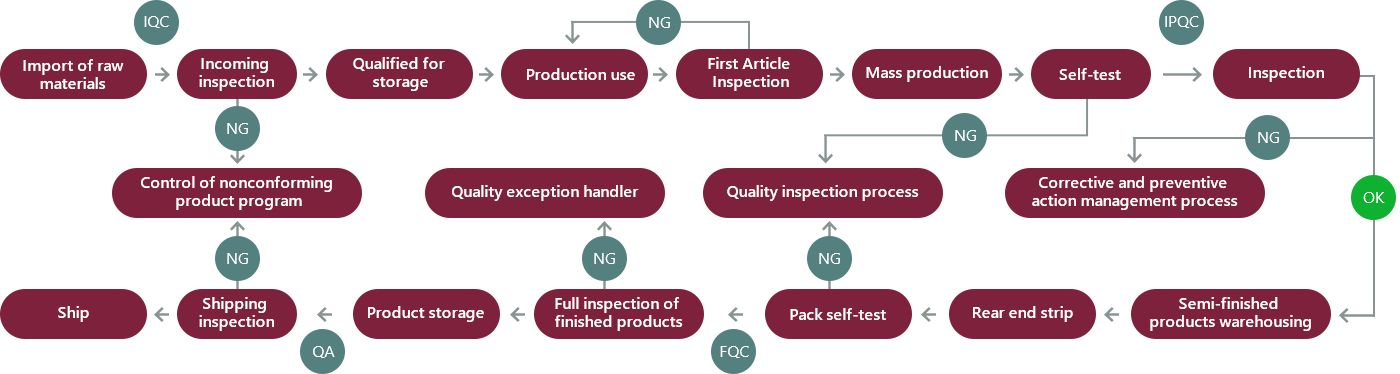

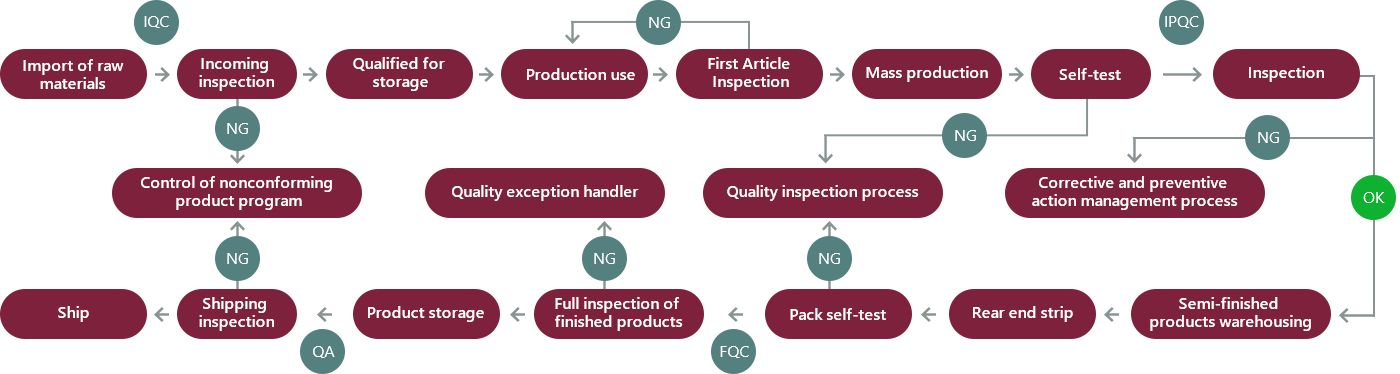

After the customer confirms the sample, mass production of the recycled coil zipper begins.

Ensure strict quality control during the production process to ensure that each product meets standards and requirements.

Conduct quality inspections on the produced recycled coil zippers to ensure that the products comply with relevant quality standards and regulations.

Check the shape, size, density, and other parameters of the coil to ensure stable product quality.

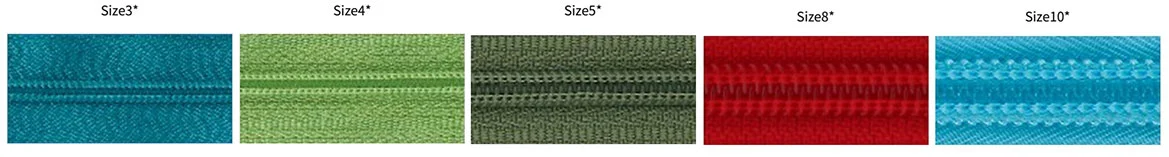

| Size / Chain Type | Classification | |||

|---|---|---|---|---|

| Close | Open | Two-way | Chain | |

| No. 3 invisible mesh | OK | / | / | OK |

| No. 4 invisible mesh | OK | / | / | OK |

| No. 3 | OK | OK | / | OK |

| No. 4 | OK | OK | / | OK |

| No. 5 | OK | OK | OK | OK |

| No. 8 | OK | OK | OK | OK |

Environmentally friendly and sustainable: Recycled coil zippers are made from recycled materials, often made from recycled nylon or other synthetic fiber materials. By reducing the need for virgin materials, it helps reduce resource consumption and environmental pollution, in line with the concept of sustainable development.

Consistent quality: Although made from recycled materials, recycled coil zippers generally have good quality and stability. Manufacturers usually strictly screen and process recycled materials to ensure that the products meet relevant quality standards and requirements.

Durability: Recycled coil zippers are generally of higher quality and can withstand prolonged use and frequent opening and closing operations, giving them a long service life. Recycled materials are also generally more durable and can meet the needs of a variety of different products.

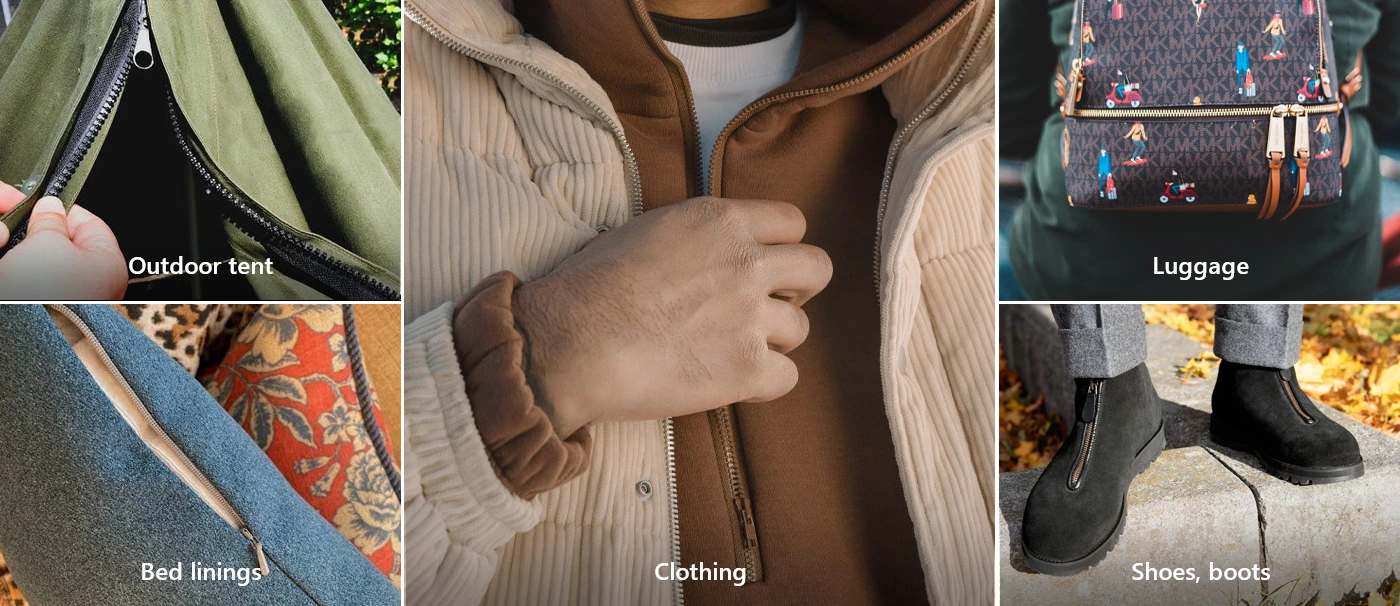

Versatility: Recycled coil zippers are suitable for a variety of different products and areas, including clothing, luggage, outdoor gear, homewares, and more. Its versatility makes it an ideal choice in the manufacture of many products.

Recycled coil zippers are widely used in the manufacture of clothing and textiles, including jackets, pants, shirts, sports equipment, and more. The use of recycled coil zippers in the manufacturing process of these products helps reduce the need for virgin materials, lowering production costs while being environmentally conscious. Bags and luggage products such as suitcases, luggage, backpacks, travel bags, etc. often use recycled coil zippers. They need to be durable and reliable, and recycled coil zippers meet these requirements while reducing the need for new materials. Regenerated coil zippers are widely used in various industries. Its environmentally friendly and sustainable characteristics make it an ideal choice in the manufacturing of many products, helping to reduce resource consumption and environmental pollution and promote the process of sustainable development.

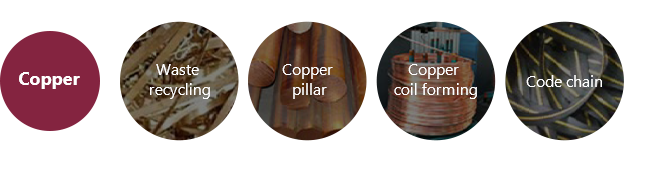

Baoxin has a high degree of environmental awareness. We have a complete environmentally friendly material recycling system to reduce factory waste residues. Not only have the chain elements been fully recycled and non-toxic regenerated cloth belts have also been manufactured using environmentally friendly materials. Currently, some of Baoxin's products have been made from 100% environmentally friendly materials, fully reducing the loss of earth resources and environmental pollution.

Shenzhen Baoxin Zipper Co., Ltd was founded in 1991, the total investment has exceeded RMB 100 million. The factory covers an area of 30,000 square meters and has more than 300 employees, with annual capacity exceeding 200 million meters. It has developed into a large zipper enterprise integrating research, development, design, production, sales and services. The company is currently a director unit of the Zipper Branch of China Hardware Products Association, and the executive vice president unit of the Guangdong Zipper Chamber of Commerce, the executive director unit of the Shenzhen Small and Medium Enterprises Development Promotion Association, the vice president of the Shenzhen Quality Association, and an outstanding enterprise in the zipper industry.

We are a zipper manufacturer in Shenzhen, China. A large zipper enterprise integrating research, development, design, production, sales, and service, specializing in zipper R&D and sales for 32 years.

Generally, it is 5-15 working days. It also depends on the order quantity and product type. If in stock, it can be shipped within one day.

Yes, we provide samples for free.

Always have pre-production samples before mass production; always have a final inspection before shipment;

If we have stock, we can accept small orders, but the MOQ of different styles fluctuates.

Of course, all products are environmentally friendly.