Excellent enterprise in the zipper industry

One-stop production of webbing, dyeing, mold making, design, etc., coil, plastic, and metal zippers of various specifications.

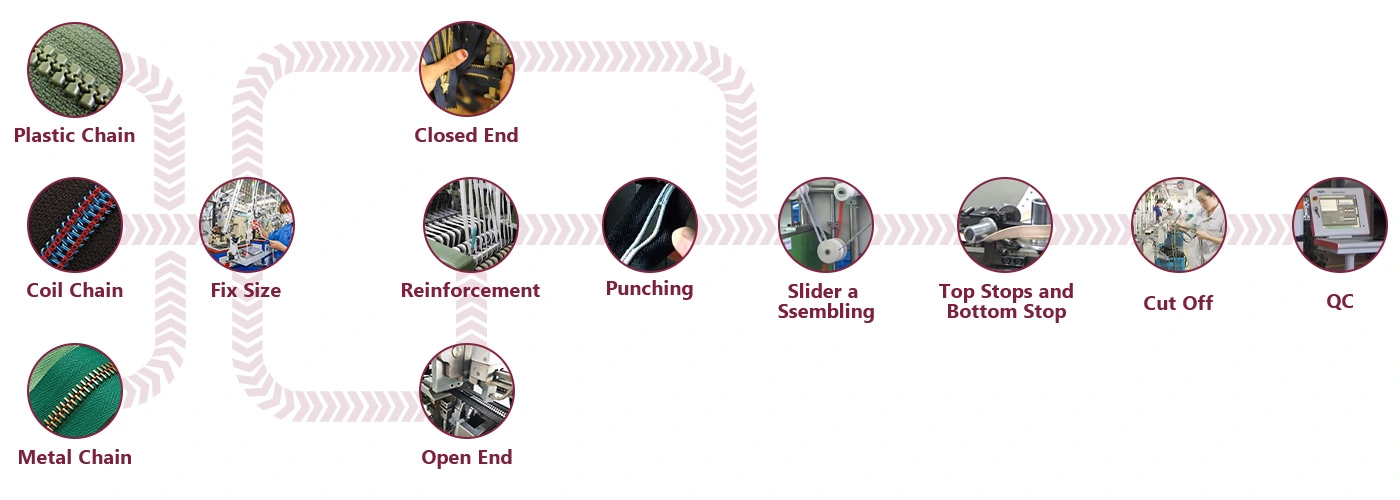

Design planning: First, communicate with the customer to determine the specifications of the zipper, including length, width, tooth size, zipper head design, etc. Develop preliminary design drawings or samples according to customer needs.

Select materials: According to the design plan, select suitable materials, such as nylon, plastic, etc. Ensure that the selected materials have good wear resistance, durability, and softness, and are also required to be color-stable and not easy to fade.

Mold Making: The mold required to make a custom opening self-locking invisible zipper. This includes zipper tooth molds, zipper tape molds, zipper puller molds, etc. The accuracy of the mold directly affects the quality of the final product.

Zipper teeth injection molding: Use a mold to injection mold the selected material into zipper teeth. This step requires ensuring that each tooth meets specifications and that the overall structure is sturdy to ensure smooth zipper opening and closing operations.

Belt production: Use a mold to inject the selected material into a zipper belt. The production of the strap requires attention to its softness and stability to ensure smooth operation and good appearance of the zipper.

Assembly: Assemble the zipper teeth and straps. This step requires manual operation by professional workers to ensure that each tooth is correctly inserted into the strap to form a complete zipper.

Zipper puller making: Design and make custom zipper pullers according to customer requirements. This may include special shapes, logos, or other personalization elements. The quality and design of the zipper puller directly affect the overall appearance and functionality of the product.

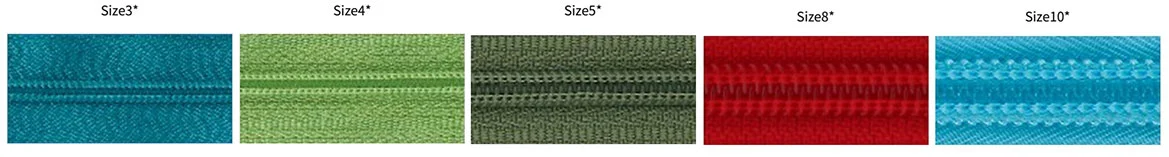

| Size / Chain Type | Classification | |||

|---|---|---|---|---|

| Close | Open | Two-way | Chain | |

| No. 3 invisible mesh | OK | / | / | OK |

| No. 4 invisible mesh | OK | / | / | OK |

| No. 3 | OK | OK | / | OK |

| No. 4 | OK | OK | / | OK |

| No. 5 | OK | OK | OK | OK |

| No. 8 | OK | OK | OK | OK |

1.Take a closer look at the appearance of the zipper. High-quality nylon zippers generally have a neat, smooth appearance with no obvious deformation or damage. Check that the zippers are evenly colored and have no fading or stains.

2.Check the teeth of the zipper to make sure they are aligned and evenly constructed. The teeth of a high-quality nylon zipper will usually fit together securely with no visible gaps. Avoid choosing a zipper with gaps between teeth or irregularities, which may affect its stability and durability.

3.Try pulling on the zipper. A high-quality Reverse Coil Zippers should open and close smoothly without getting stuck or sluggish. It should feel easy when you pull, without requiring too much force.

4.Check the manufacturing process and materials of the zipper slider. High-quality Reverse Coil Zippers usually have strong and smooth sliders that are less likely to break or rust during use.

5.The zipper puller is another part to pay attention to. High-quality Reverse Coil Zippers usually use strong and durable pullers to ensure that they are not easily deformed, broken, or rusted. The design of the slider should also be ergonomic and easy to use.

6.Try applying moderate traction on both ends of the zipper to test the zipper's endurance. A high-quality nylon zipper should be able to withstand moderate pulling without breaking easily.

1.For outdoor products, raincoats, or products that require waterproofing, nylon coil zippers need to have a waterproof design to ensure that the interior of the item is protected from moisture.

2.For products used in extreme temperature conditions, nylon coil zippers need to be resistant to high or low temperatures. This ensures that the zipper will function properly in a variety of environments.

3.In environments exposed to chemicals, such as industrial supplies or laboratory equipment, nylon coil zippers may need to be chemically resistant to avoid damage due to chemical effects.

4.For outdoor items such as tents or camping equipment, nylon coil zippers may need to be UV-resistant to prevent color fading or material degradation caused by prolonged exposure to sunlight.

5.Where greater strength and durability are required, nylon coil zippers may have a ripstop design, making them more difficult to tear or break.

6.Some applications may be sensitive to zipper noise, such as tents used at night. Nylon coil zippers may need to be designed to be silent or less noisy.

7.Some high-end products may use self-healing technology, which means that after being slightly damaged, the nylon coil zipper can repair itself and extend its service life.

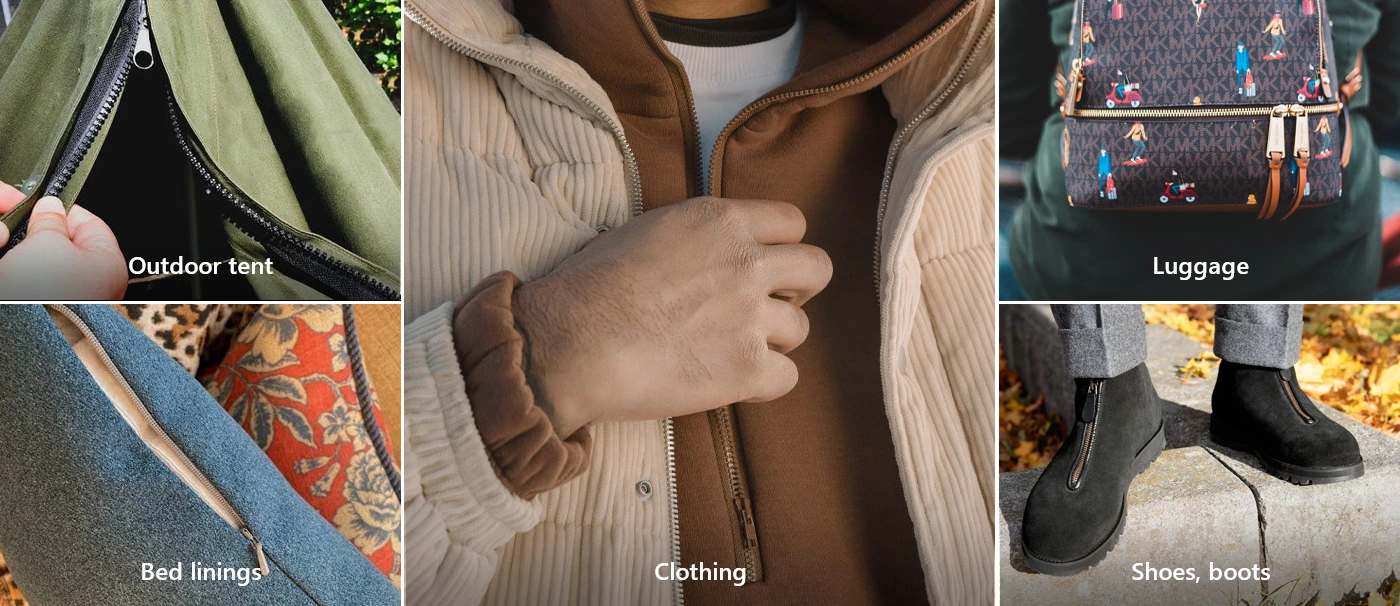

Nylon coil zippers are widely used in various fields such as pants, jackets, dresses, shoes, tents, sleeping bags, mountaineering bags, backpacks, handbags, suitcases, pillowcases, curtains, and beds due to their lightweight, wear-resistant, and durable properties. Supplies, etc., the application fields of nylon coil zippers are very wide, covering all aspects of daily life, and providing convenient and reliable closing solutions for various products.

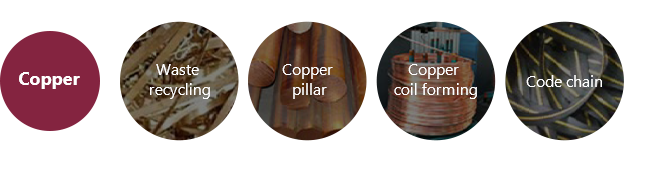

Baoxin has a high degree of environmental awareness. We have a complete environmentally friendly material recycling system to reduce factory waste residues. Not only have the chain elements been fully recycled and non-toxic regenerated cloth belts have also been manufactured using environmentally friendly materials. Currently, some of Baoxin's products have been made from 100% environmentally friendly materials, fully reducing the loss of earth resources and environmental pollution.

Shenzhen Baoxin Zipper Co., Ltd was founded in 1991, the total investment has exceeded RMB 100 million. The factory covers an area of 30,000 square meters and has more than 300 employees, with annual capacity exceeding 200 million meters. It has developed into a large zipper enterprise integrating research, development, design, production, sales and services. The company is currently a director unit of the Zipper Branch of China Hardware Products Association, and the executive vice president unit of the Guangdong Zipper Chamber of Commerce, the executive director unit of the Shenzhen Small and Medium Enterprises Development Promotion Association, the vice president of the Shenzhen Quality Association, and an outstanding enterprise in the zipper industry.

We are a zipper manufacturer in Shenzhen, China. A large zipper enterprise integrating research, development, design, production, sales, and service, specializing in zipper R&D and sales for 32 years.

Generally, it is 5-15 working days. It also depends on the order quantity and product type. If in stock, it can be shipped within one day.

Yes, we provide samples for free.

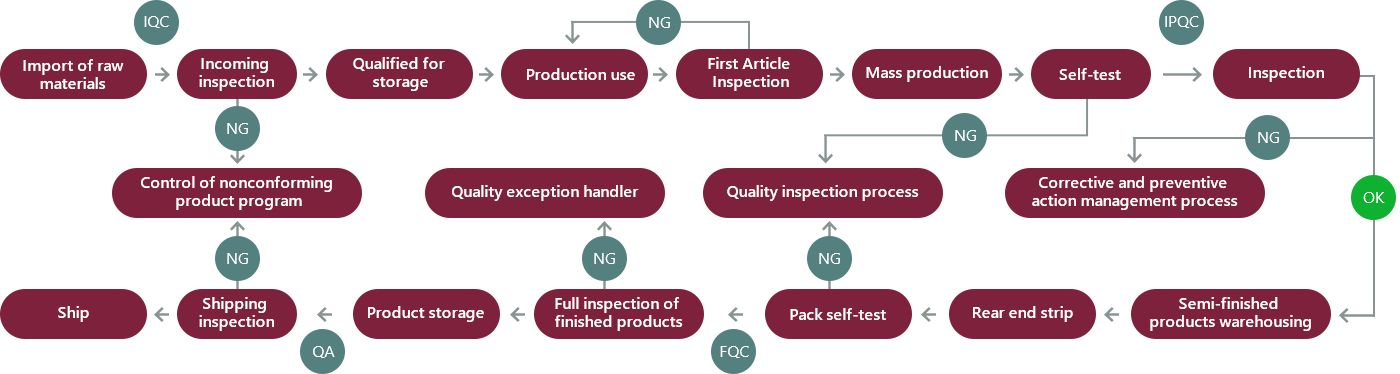

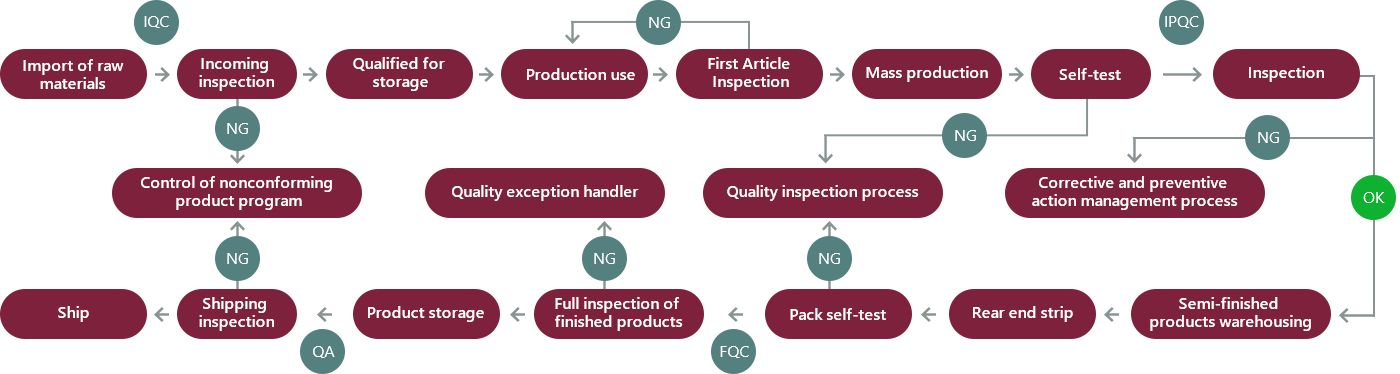

Always have pre-production samples before mass production; always have a final inspection before shipment;

If we have stock, we can accept small orders, but the MOQ of different styles fluctuates.

Of course, all products are environmentally friendly.